Product display

Location::Home > Product display

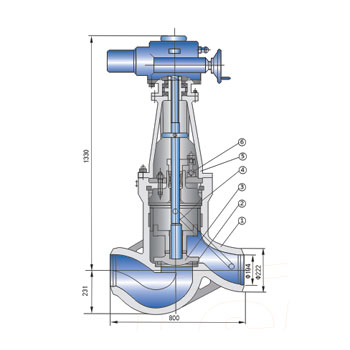

Special Power Station-stop-check Valve

Brief Structure

1. Valve pressure from the tight seal, the higher the medium pressure, the better the sealing performance, the use of molding ring asbestos packing.

2. Valve in the valve body for lifting movements, before the operation of the stem lift, press the media pressure will automatically open the valve. When the boiler fails, the valve inlet pressure decreases, the media back to the valve quickly shut down.

3. Valve bracket and electric device connected to the valve to achieve a better seal.

4. Valve and valve seat seal and the use of drilling-based carbide pl-asma spray welding, wear, anti-scratch performance.

5. Stem surface corrosion treatment by nitriding, with good corrosion resistance and scratch resistance.

6. The valve can be hand, electric switch, manually cut off the power automatically, hand wheel clockwise rotation to close the valve.

Use

Cut-off valve installed in the combined steam engine on the main steam pipe, as to prevent the media back, when the boiler failure, the media pressure quickly shut the valve, the boiler play a security role.

Installation Notes

1.The valve must be vertically mounted on the pipeline, with the stem upward and the medium flowing in under the seat ring.

2.Place the electric actuator in such an environment as non-corrosive non-explosive gas and with the ambient temperature-20~40°C and the related humidity 80%.

3.For the electric actuator, when used with the pipeline of a temperature below 350°C, use semi-fluid Li-base lubricating oil(Q/SY1002-65) and, when the said temperature is higher than 350°C,use GB492-2N-4 sodium-base lubricating grease.

View product detail data

Copyright © 2017

Shanghai Power Plant Valve Factory Co.,Ltd. All Rights Reserved.

Technical support:Prcvm