Product display

Location::Home > Product display

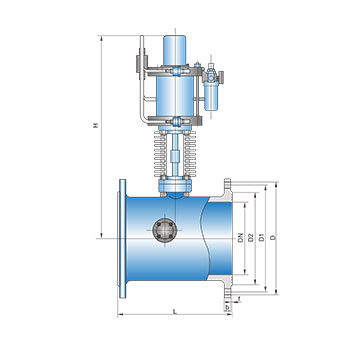

Quick Closure Steam Extraction Check Valve

DN100-800

Use

Quick closure steam extraction check valve is also called quick closure inverted valve or quick shutdown.This valve is mainly applied to the emergent non-return and pipeline system of power plant steam turbine.It can shut down within 0.5~1s to avoid damaging steam turbine due to the inverse flow of steam and condensed water inside pipeline system

Feature

This valve consists of valve body,quick clasedown assistance device and control system.Valve flap adopts large angle oblique placement to shorten on-off stroke of startup and shutoff.There are also gas(liquid) cylinder to help closure and quickly shut down vlave flap within 0.5~1s.

This vlave adopts eccentric metal hard seal structure.Through the thrust functioned by gas (liquid) cylinder on valve flap,the valve can not only achieve quick closure and non-return function but also perform disconnection function under the condition of low pressure difference.

Seal gland adopts hard surface contact and valve flap seal surface is processed through resurfacing welding by utilizing high-abrasion material to have enhanced abrasion and flushing performance of valve flap under the medium with high flow speed,thus enhancing seal performance of valve under operatingcondition of high temperature and pressure. Optimized valve rod eccentric position makes valve flap at smaller rotary moment of inertia in time of closure to reduce the impact of valve flap seal surface on valve seat.Unique oblique cone seal surface structure can ensure reliable seal as well as smooth startup and shutoff,and will not result in seizure phenomenon of valve flap due to quick closure and high pressure. Three-dimensional accentric hard seal structure realizes non-friction of seal gland in time of startup and shutoff,namely separation after startup and seal after closing contact.It can automatically compensate the abrasion of seal surface caused by long-term use,thus greatly enhancing service lifetime of valve. This vlave can be applied to occasions such as water,gas,steam,petroleum products.Applicable temperature:-29~425°C(carbon steel), -29~550°C. (alloy steel), -196~600°C(stainless steel).

Working Principle

(1) normal state

When the turbine starts to work, the electromagnet is energized and the high pressure oil (compressed air) enters the rod of the action oil (gas) cylinder of the extraction check valve via the solenoid valve to push the piston upwards and the valve is under pressure Open, action cylinder rodless cavity through the solenoid valve back to the oil, pneumatic exhaust through the exhaust valve. Electromagnet loss of power, high pressure oil (compressed air) through the solenoid valve into the extraction valve check valve action oil (gas) cylinder of the rod cavity, so that the valve quickly closed, and keep pumping (gas) cylinder pressure.

(2) the state of the accident

The electric signal of the accident causes the electromagnet to lose power, the solenoid valve is reset, the lever of the action oil (gas) cylinder is switched to the oil return (exhaust), and the rod of the action oil (gas) , So that the valve flap action, quickly cut off the pipeline.

View product detail data

Copyright © 2017

Shanghai Power Plant Valve Factory Co.,Ltd. All Rights Reserved.

Technical support:Prcvm