Product display

Location::Home > Product display

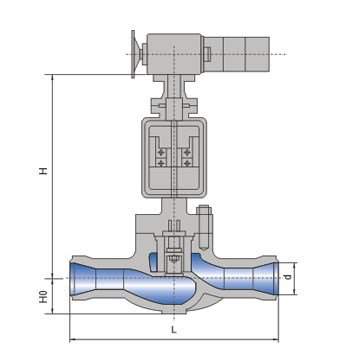

Electric Water Supply Control Valve

DN50-300

PN250-320

T968Y Series

Descriptions

Water supply control valve, also known as anti-cavitation, low noise, high pressure differential valve, is our factory engineering and technical personnel to meet the 50~600WM supporting the development of thermal power units and the new control valve, the series of products after repeated improvements, continuous improvement , Has novelty and advanced, has been rated as "Shanghai New Product Award", "China New Technology New Products Expo" Gold Award, "Shanghai High-tech Products", China Power Enterprises Federation recognized the priority to promote the patent product.

Use

Installed in the power plant boiler feed pipe for flow control.

Specifications

Nominal pressure: PN25~32

Nominal diameter: DN50~300mm

Operating temperature: ≤300°C

Suitable medium: boiler feed water.

Connection: Butt welding.

Characteristic curve: linear, equal percentage.

Rated flow coefficient Kv value or rated flow: According to the actual process parameters provided by the user design, manufacture.

Manipulation methods: electric (straight stroke, angular stroke).

Structural Features

1. This series of products with a completely removable structure, the valve cavity (including the valve seat, the valve core, throttling components, seals, etc.) can be taken out of the valve cavity, maintenance is very convenient. Valve body without cutting from the pipe, long-term use.

2. The spool is a plunger body balanced structure, low operating torque, high adjustment sensitivity.

3. Throttle assembly consists of perforated plate manifold flow restrictor and sleeve thimble, and with a flow hood, which has a small flow of high pressure differential cavitation, good performance of large flow regulation, fluid discharge comb Flow noise-free integrated features, fully meet the requirements of the boiler feed conditions, and effectively achieve high temperature, high pressure fluid flow control. Adjustable performance, high regulation accuracy.

4. The throttle ring can work within 55% of the valve stroke, to achieve multi-stage decompression throttling.

5. Spool valve seat and valve sealing surface too hard alloy Division, anti-erosion, corrosion.

6. There are two valve inherent flow characteristics: linear or equal percentage. Valve in the closed state, "0" opening, the amount of leakage is zero.

View product detail data

Copyright © 2017

Shanghai Power Plant Valve Factory Co.,Ltd. All Rights Reserved.

Technical support:Prcvm